Introduction:

Feather dewatering machines have become integral in the poultry processing industry, revolutionizing the way feathers are handled after the slaughtering process. These machines play a crucial role in reducing waste, improving efficiency, and ensuring a more sustainable approach to poultry production.

The Feather Dewatering Process:

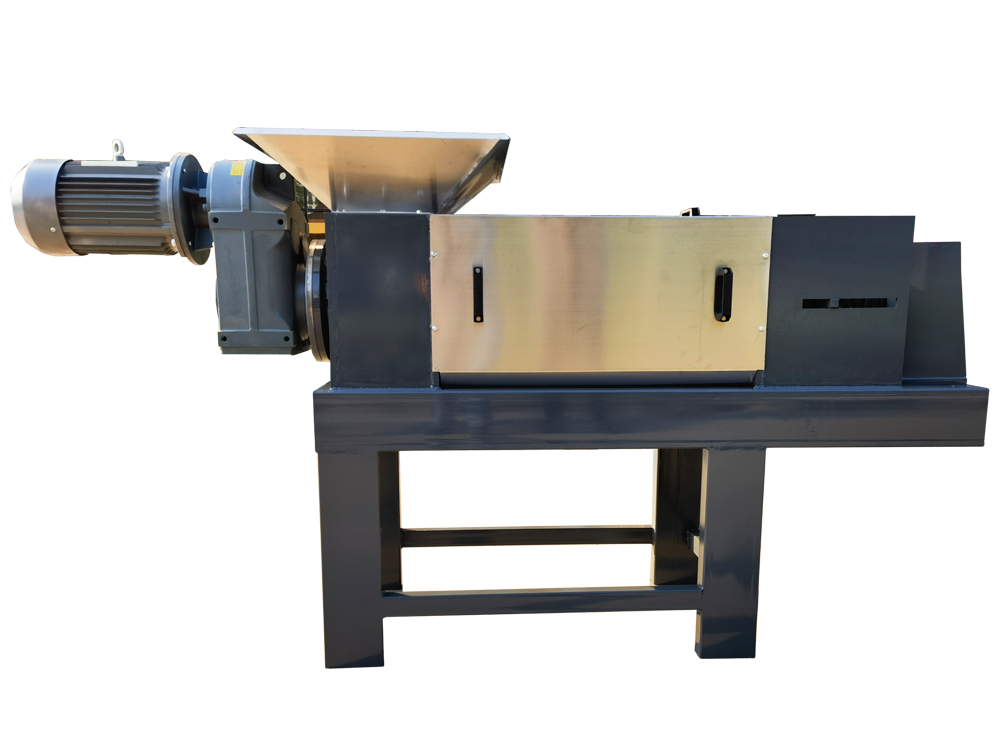

Feather dewatering machines are designed to efficiently remove excess water from feathers, a byproduct of poultry processing. After birds are slaughtered, feathers are collected for various purposes such as making feather meal or other products. Traditional methods of feather drying involve time-consuming air-drying or using energy-intensive methods like hot air drying. Feather dewatering machines offer a faster and more energy-efficient alternative.

Key Features of Feather Dewatering Machines:

Centrifugal Force: These machines utilize centrifugal force to separate water from feathers. The spinning motion of the machine expels water droplets from the feathers, leaving them drier and more suitable for further processing.

Time Efficiency: Feather dewatering machines significantly reduce the drying time compared to traditional methods. This time efficiency translates to increased productivity and quicker turnaround in poultry processing plants.

Energy Efficiency: By employing centrifugal force, feather dewatering machines consume less energy compared to conventional drying methods. This not only reduces operational costs but also aligns with the industry's growing emphasis on sustainability.

Improved Feather Quality: The gentle nature of feather dewatering machines ensures that feathers are not damaged during the process. This results in higher-quality feathers that can be used for a variety of applications, including feather meal production for animal feed.

Benefits of Feather Dewatering Machines:

Waste Reduction: Efficient water removal means fewer feathers are wasted due to spoilage or degradation. This reduction in waste contributes to a more sustainable and environmentally friendly poultry processing industry.

Increased Profitability: The combination of time and energy efficiency leads to increased overall profitability for poultry processing plants. Quicker processing times and reduced operational costs positively impact the bottom line.

Sustainable Practices: Feather dewatering machines align with the industry's push towards sustainability. By reducing energy consumption and waste, these machines contribute to a more environmentally conscious approach to poultry production.

Conclusion:

Feather dewatering machines have emerged as a game-changer in the poultry processing industry, offering a more efficient and sustainable solution for handling feathers. With their ability to reduce waste, improve processing times, and enhance overall feather quality, these machines are poised to play a pivotal role in shaping the future of poultry production. As the industry continues to evolve, investments in innovative technologies like feather dewatering machines will be key to maintaining a competitive edge and promoting sustainability.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China